Over the last 20 years, I have made up a couple of hundred cutting boards most end grain some of which are pictured in this article. During that time I had to find a glue that was strong and had good gap-filling properties. I tried a few different types of glue over that time in order to find the best glue for cutting boards.

Both Titebond III and Gorilla glue are the best glues for cutting boards either long-grain or end-grain boards. Both glues are food-safe and water-resistant with Titebond III being waterproof.

In this article, I’ll delve into various types of glue suitable for cutting boards based on their durability, food safety features, and water resistance capabilities.

Pro Tip and My Recommendation 💭

Titebond III is my personal favorite wood glue for cutting boards. It is food safe, waterproof, and has excellent gap-filling properties. These 3 things are key in getting strong joints for cutting boards!

Key Takeaways

- Titebond III is considered the best glue for cutting boards due to its waterproof nature and FDA approval for indirect food contact.

- Gorilla Wood Glue is another top pick for cutting board glue, offering both FDA compliance and water resistance.

- Proper surface preparation, including cleaning and sanding, is essential before applying glue to ensure a strong bond.

- When using glue on cutting boards, apply a thin layer evenly with a brush or roller and use clamps to hold the pieces together while drying.

Factors to Consider for Choosing the Best Glue for Cutting Boards

When choosing the best glue for cutting boards, there are two key factors to consider: food safety and water resistance.

Food Safety

Sure, cutting boards serve a critical role in my kitchen. Selecting safe adhesives for cutting boards becomes equally essential to ensure there’s no chemical seepage into your food during preparation.

I stick with Titebond III or Elmer’s Carpenters Wood Glue Max as they’re both food-safe options for bonding wooden surfaces and are FDA approved for direct food contact. Always check the label on any glue you choose and make sure it is formulated without harmful chemicals that could compromise your health.

Water Resistance

Water resistance is paramount when selecting the ideal glue for your cutting board. Why? Well, think about it – your cutting board constantly battles with water and moisture from wiping or food preparation activities.

Thus, waterproof adhesive or water-resistant wood glue becomes a necessary ally in preserving its longevity.

Selecting the right kind of adhesive can mean the difference between a warp-free and durable cutting board, versus one that disintegrates prematurely. Water-resistant PVA adhesive such as Titebond III fits this profile perfectly.

Loved by woodworkers worldwide, this particular sealant stands out for its proven waterproof properties and FDA approval status for indirect food contact.

Further still, gaps and holes that may develop on your wooden kitchen companions can be salvaged using high-quality glues which are both food-safe and weatherproof like Gorilla Wood Glue or different versions of Titebond.

This ensures you continue creating culinary masterpieces without worry over toxic trace elements leaching into your meals owing to substandard adhesives used on the boards.

So yes! The water-resistance quality of the glue is not just an afterthought; it’s a critical aspect you should always consider when choosing an adhesive specifically designed to withstand routine exposure to moisture in busy kitchens.

Top Picks for Best Glue for Cutting Boards

When it comes to the best glue for cutting boards, two top contenders stand out: Titebond III and Gorilla Wood Glue.

Titebond III

I’ve found that Titebond III holds a special place in my toolbox. Revered as one of the top picks for the best glue for cutting boards, its high-performance adhesive capabilities make all the difference.

As a reliable bonding agent for long-lasting cutting boards, it’s cherished by professionals and woodworking enthusiasts alike. The confidence comes from knowing it is FDA-approved for indirect food contact and prioritizing safety during meal preparations.

Its waterproof nature offers resilience against water damage – a perfect fit not only for indoor but outdoor gluing too! But what makes me reach out invariably to my beloved bottle of Titebond III?

I wrote an article comparing both Titebond 2 and Titebond 3 and which is better. Here is what I found.

It’s an uncompromising strength and durability offered by this PVA (polyvinyl acetate) glue which has demonstrated an unmatched level of reliability in crafting enduring cutting boards time after time, no matter the climate or environment.

Gorilla Wood Glue

Gorilla Wood Glue is one of the top picks for the best glue for cutting boards. Not only is it highly recommended by professionals, but it also complies with FDA standards for indirect food contact once cured, making it safe to use on your cutting board.

Its waterproof properties add an extra layer of durability and protection, ensuring that your cutting board stays intact even when exposed to water or moisture.

I get my Gorilla glue here on Amazon as they seem to have the best price.

With its strong adhesive qualities, Gorilla Wood Glue is a reliable choice for all your kitchen needs, providing a secure and long-lasting bond between the wooden surfaces.

Tips for Using Glue on Cutting Boards

To ensure a successful bond when using glue on cutting boards, make sure to properly prepare the surface by removing any debris and ensuring it is clean and dry. Apply the glue evenly across the surfaces to be bonded, using a brush or spreader for thorough coverage.

Allow enough time for the glue to fully dry before moving or using the cutting board. Dispose of any excess or spilled glue promptly, as dried glue can be difficult to remove.

Surface Preparation

To ensure a strong and durable bond between the pieces of your cutting board, proper surface preparation is essential.

Here are some key steps to follow:

- Clean the wood surface: Start by cleaning the wood surface thoroughly to remove any dirt, dust, or contaminants. Use a damp cloth or sponge and mild detergent if necessary. Ensure that the wood is completely dry before moving on to the next step.

- Sanding: Sanding the wood surface helps create a rough texture that allows the glue to adhere better. Use sandpaper with medium grit (around 120-150) and sand along the grain of the wood. Make sure to sand both sides that will be joined together for an even bond.

- Remove excess sawdust: After sanding, wipe away any sawdust from the wood surface using a soft brush or cloth. This step ensures that there are no particles trapped between the glued surfaces, which could weaken the bond.

- Apply glue evenly: Apply an even layer of glue onto one of the surfaces using a brush or roller applicator. Make sure you cover the entire area with a thin but sufficient amount of glue.

- Clamping: Once you have applied the glue, carefully align and press the two surfaces together firmly. Use clamps to hold them in place while drying according to the manufacturer’s instructions.

Glue Application

When applying glue to cutting boards, it is important to follow proper techniques to ensure a strong and secure bond.

Here are some tips for successful glue application:

- Surface preparation: Before applying the glue, make sure the surfaces of the cutting board pieces are clean and free from dust or debris. Sanding the surfaces lightly can help create a better bond.

- Glue selection: Choose a water-resistant or waterproof wood glue, such as Titebond III or Gorilla Wood Glue, specifically designed for bonding wood. These glues have superior adhesion properties and can withstand exposure to moisture.

- Apply a thin layer: Using a brush or a small roller, apply a thin, even layer of glue on one of the surfaces you wish to join. Be careful not to use excessive amounts of glue, as it may result in messy joints or weak bonds.

- Spread evenly: Use a spreader or an old credit card to distribute and spread the glue evenly over the surface. This ensures that every part of the joint is fully covered with adhesive.

- Clamp for pressure: Once you’ve applied the glue and spread it evenly, carefully join the two pieces of the cutting board together. Apply clamping pressure using woodworking clamps to ensure a tight bond.

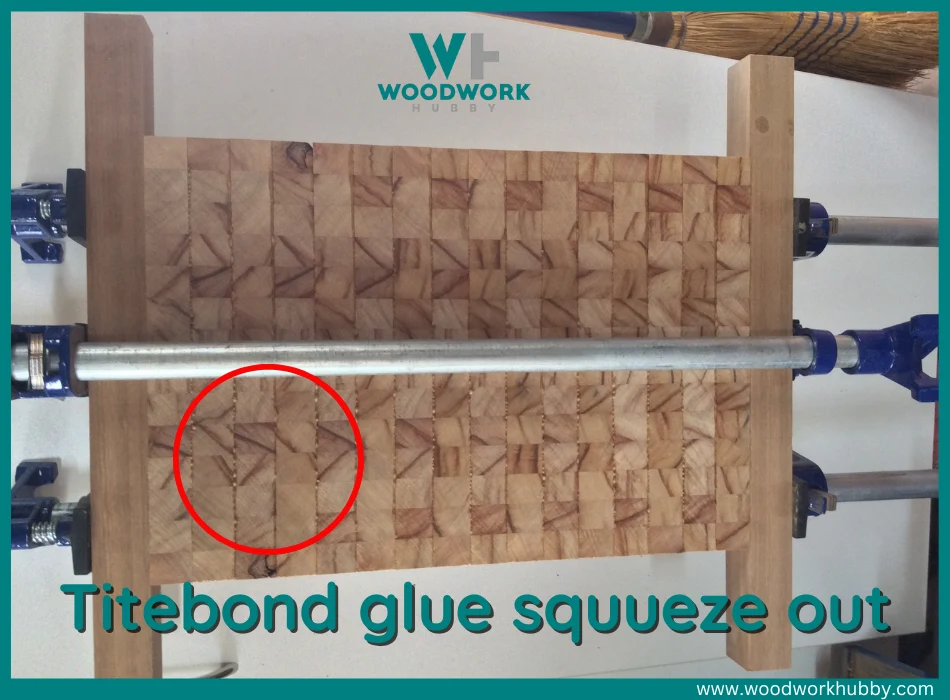

- Wipe off excess: After clamping, wipe away any excess glue that may have squeezed out from the joint using a damp cloth. This prevents hardened glue from interfering with finishing or staining processes later on.

- Drying time and clean-up: Follow the manufacturer’s instructions regarding drying time before removing clamps or further handling the cutting board assembly. Clean up any tools used for spreading and applying glue while they are still wet with warm soapy water.

Drying time and Clean-up

When working with glue on cutting boards, it’s important to consider the drying time and proper clean-up to ensure a strong and durable bond.

Here are some tips to keep in mind:

- Allow ample drying time: The drying time for cutting board glue can vary depending on the type of adhesive used. However, it is generally recommended to wait at least 3 hours before removing any clamps or applying pressure on the glued joints. I personally leave them in clamps for 24 hours as that is the cue time of Titebond wood glue.

- Follow manufacturer’s instructions: Different glues may have specific instructions regarding drying time and temperature requirements. It’s essential to read and follow the manufacturer’s instructions carefully to achieve optimal results.

- Patience is key: While waiting for the glue to dry, it’s best to exercise patience and avoid rushing the process. Leaving the cutting board in clamps overnight or for a longer period can help ensure that the adhesive fully cures, resulting in a stronger bond.

- Clean excess glue immediately: It’s crucial to clean up any excess glue before it dries completely. Use a damp cloth or sponge to wipe away any spills or smudges on the surface of the cutting board. If necessary, use a scraping tool or sandpaper to remove dried glue residue.

- Check for cured spots: Once the glue has dried, inspect the joints carefully for any uncured spots or weak bonds. If needed, reapply additional adhesive and allow it to dry according to the manufacturer’s instructions.

See my article here on how long it takes Gorilla wood glue to dry.

Getting good joints on cutting boards requires a clean and almost invisible glue joint. Here are the tests I did to see if Titebond wood glue dries clear.

Conclusion – Best Glue For Cutting Boards

In conclusion, when it comes to choosing the best glue for cutting boards, Titebond III reigns supreme. Its superior waterproof properties and food-safe composition make it an ideal choice for assembling durable cutting boards.

So, whether you’re a professional woodworker or a DIY enthusiast, Titebond III is sure to provide the strong bond you need for your kitchen’s favorite tool.

FAQs

1. What is the best glue for cutting boards?

The best glue for cutting boards is a food-safe, waterproof adhesive that can withstand high temperatures and repeated washing. Food-grade epoxy or polyurethane glues are commonly recommended options.

2. Can I use regular wood glue for repairing a cutting board?

Regular wood glue is not suitable for repairing a cutting board as it is not waterproof and may degrade over time when exposed to moisture and frequent washing. It’s important to use a specific adhesive designed for food-safe applications.

3. How should I apply glue when repairing a cutting board?

When applying glue to repair a cutting board, ensure both surfaces are clean and dry. Apply an even layer of adhesive to one surface, then press the broken pieces together firmly. Use clamps or heavy objects to hold them in place until the glue dries completely.

4. How long does it take for the glue to dry on a repaired cutting board?

Drying times vary depending on the type of adhesive used and environmental conditions such as temperature and humidity. Generally, it is recommended to allow at least 24 hours for the glued areas to cure properly before using your cutting board again.