When I started my woodwork journey, I didn’t have excess money to buy all the latest tools. I bought myself a table saw and then I often wondered if I could double my table saw as a basic router? After many years of working with both tools, I thought I should compile the information I have learned to help you the answer to this common question.

In general, a table saw cannot be used as a router due to its straight and fixed blade position. Table saws can only cut straight cuts while routers can perform a variety of other cuts thanks to the various router bits available. In saying this, both table saws and routers can perform some cuts that are the same.

Furthermore, it is possible to use a table saw bench for a router which is commonly known as a router table. This article will briefly go over how you can add a router to your table saw extension.

But first, you’ll discover how table saws and router tables differ. You’ll also learn the cuts that both these tools can make, and what product gives you the option to hybridize and save valuable workspace.

How Table Saws and Routers Differ

It is essential to note that a router is not a saw and a saw is not a router, even though they have a few similarities. They come with different characteristics and accessories and are ideally used for different types of projects.

See my full guide on how long do router bits last? This may surprise you!

Table Saws

This versatile power tool is commonly known as the workhorse of a woodshop because it is more productive than all other woodworking machines. Table saws can perform the following cuts:

- Ripping of wood

- Crosscuts

- Miter cuts

- Dado

- Rabbet

- Chamfers

- Straightening edges – See more on using a table saw as a jointer

As you can see from the above cuts they all possess similar characteristics in that all the cuts are straight along a linear line. Yes, you can tilt the blade over, but it still only makes straight cuts.

I gathered the knowledge from my own experiences and my woodworking peers and we put together this full article on the 12 best table saws for Dado cuts.

Routers & Router Tables

A handheld router is essentially the same as a router table in that the router is flipped upside down and fixed below a bench or sometimes on the end of your table saw and spins in an anti-clockwise direction.

Routers can take a variety of router bits that are round in nature and have different shapes to them. A router can make the following cuts:

- All types of Decorative edge work to wood

- Dado

- Rabbet

- Chamfers

- Dovetails

- Mortise and tenons

- Rounded cuts

- Straightening edges

- Template cuts

The benefit of router tables over handheld routers is that smaller stock can be shaped and a fence can be used for precise cuts along the edges of boards.

Table saws are considered for reducing wood stock

Since a table saw does not have the capacity to cut wood following a template, it cannot be used as a table router because it can be configured with a special router to cut according to a template.

Similarly, a table saw can only cut in straight lines and is not suitable for making non-linear designs. Router tables can follow and cut a design drawn on some wood and can even make multiple designs.

See my list of what woodworking tools you should get when starting out.

What Is a Table Saw Router?

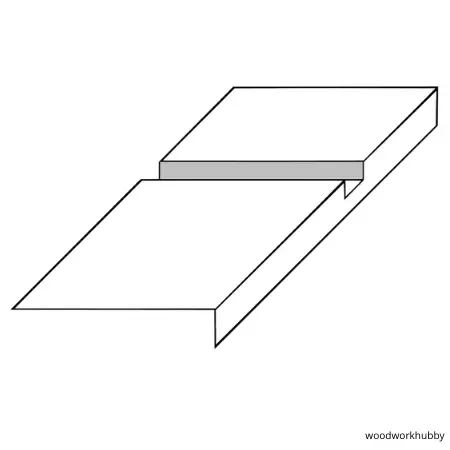

A table saw router is a table saw with a router mounted upside down at one end of the table. Because both tools can be lowered below the surface, this allows great use of 2 tools within one space.

See my full list of the best table saws under $1500. It’s well worth a look.

One of the biggest challenges faced by woodworkers is limited shop space. Making space for required tools and having a remaining space to work is a challenge, even if your workplace is a garden shed, a spacious garage, or a spot in an industrial complex. The table saw, although the cornerstone of a workshop, is one of the biggest space hogs.

The image below is my homemade table saw with a built-in router.

Cuts That Are Similar Between a Table Saw and Router

Router tables are generally better for delicate jobs, whereas table saws are ideal for straight cutting and sawing jobs. They are both efficient woodworking tools in their own respective areas but also possess a few similarities. The below cuts are the most common cuts that both table saws and routers can perform.

Dado

A dado is basically a trench in a board that does not go all the way through. Dado’s are commonly used where a shelf would join a side gable on a bookshelf for example. The traditional method of joining is the use of a Dado.

A table saw does this cut by setting the blade height to the depth of the cut and making multiple passes.

A router is much quicker at this type of joint and neater.

Rabbet

A Rabbet is similar to a dado in that is like a trench but a rabbet is done on the end or side of a board. A Rabbet is open-ended on one side and is commonly used in drawer members.

A table saw needs 2 cuts to make this joint. A router will do it in one pass.

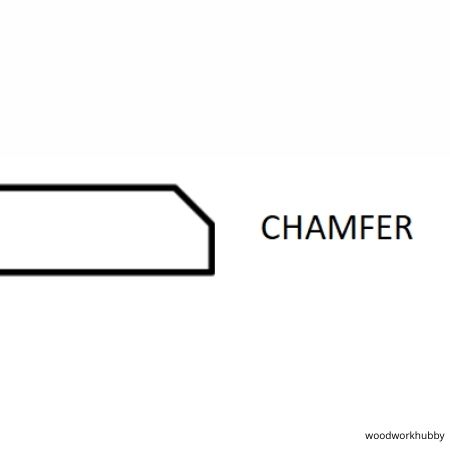

Chamfers

A Chamfer is basically a bevel that is made on the edge of a board that is 45 degrees to both faces. It is decorative in nature.

A table saw can only do straight through Chamfers and requires the blade to be tilted to 45 degrees.

A router can do more types of chamfers with more decorative results.

These are the most common types of joints that both table saws and routers can both perform. One other might be straightening boards. I have an article here that explains more about how to use a table saw as a jointer.

There may be a few other common cuts between these tools but they would be outside of what a beginner may need.

How Do You Turn a Table Saw Into a Router Table?

While the specifics of turning a table saw into a router can be gleaned from the video below and may vary depending on the workbench and table saw configuration in your case, there are essentially four broad steps you need to take.

Keep in mind, I will assume here that you will be keeping your table saw and mounting the router off to one side. This is how I would do it.

- Make room beside your table saw using the best available spot. You can also make use of your current table saw fence. You can alternatively start with a simple workbench.

- Drill a broad hole in the workbench close enough to one side that your arm can stretch one-third of the way past the hole. The width of the hole is contingent on the router you choose to use.

- Turn a router upside down and pop it through the hole. This step is the most labor-intensive as hand routers come with their own supporting lift, which only gets in the way when you’re using the router to build a router table. I suggest buying a good router lift or making your own. The video below shows you how.

- Fix the router in place. This is the final step and is quite crucial because you’ll need to use the right fixings for the router such that it can stand up to any resistance it faces when you place huge blocks of wood on it.

How to build a router table

DIY router lift

Pros And Cons Of Adding a Router To Your Table Saw

Having read the article so far, you have a few options. The first is to go buy a router and a workbench. The second is to convert a table saw into a router table. But the best of both worlds is in adding a router to your table saw. Here are the pros and cons of doing this:

The advantages

- Saves space – When you’re not using two separate workstations for two woodworking tools, you save a lot of space that can go towards a polishing station or even storage. Having your router and table saw on the same table is also smart if you don’t have a large space to accommodate a router table in addition to a table saw.

- Saves time – If you work on medium-scale projects where cutting and chopping is soon followed by detailing, you save a lot of time you’d otherwise spend walking between the two machines.

- Saves money – This is more of a conditional advantage because sometimes, the project of adding a router to the table saw can be more expensive than getting a used router table. However, in most cases, you save money by adding an extension rather than buying a separate router table.

The drawbacks

- Not novice-friendly – While novice woodworkers can get help setting up a table saw router table combo, trying to create such a hybrid workstation isn’t accessible to most new woodworkers. Unfortunately, they’re the ones who need such hybrid tables because the advanced woodworkers already have router tables and table saws alongside enough space for each.

- Safety risks – As a woodworker, you constantly engage with tools that can harm your limbs. But since these tools are made entirely by a business, there’s a sense of security in the fact that they have probably done their due diligence and testing to avoid liability. When you create a tool like a table saw router table combo, you open yourself up to potential harm with no one to hold accountable.

Best Table Saw Router Table Package

When it comes to hybridizing a table saw and a router table, there are certain safety risks that can be minimized by getting a template that supports the process. One such product is the Infinity Tools Table Saw Router Table package.

Here are the advantages of opting for this instead of trying to hybridize your standard table saw from scratch.

- Standard template for different industry-wide table saw sizes – You’re not going to get a table saw that’s conducive to router attachment. Instead, you’ll get a template that sits atop your hardware (or replaces the top of your table saw platform) and can guide the placement and size of holes that need to be drilled. It is crucial for such a template to match your table saw. The Infinity Tools Package accommodates saws with 36-inch (914mm) fences as well as 50 (1270mm) or 52-inch (1320.8 mm) fences.

- Secure router attachment – As you learned above, the greatest drawback of hybridizing your workstation is the safety risk that comes with an unstable router being tacked onto your table saw. However, with the Infinity Tools package, the symmetrical router-hole placement alongside a precise router plate helps create as secure a table saw router table as is possible for a DIY project.

- High-Quality Material – This isn’t a glorified MDF project shipped as a high-end wood product. It features a Baltic birchwood plywood core and is sturdy enough to be safe and reliable for your woodworking needs.

Final Thoughts – Can You Use a Table Saw As a Router?

Using a table saw as a router is neither practical nor recommended. However, you can turn a table saw into a table router, though this is more expensive than adding a router to a workbench. Either way, the job of a saw isn’t the same as a router, even if both have certain cuts in common.