Anybody who has tried their hand at a DIY project or two will invariably end up with a random assortment of parts and fastenings lying around, but can these leftovers be used for anything? Specifically, can you use machine screws in wood?

Machine screws are not recommended for use in wood. Machine screws are specifically designed for work with metal, and will not perform their intended task as well if used in wood. This is largely due to their thread size and count.

For example, machine screws can work with wood; however, they will be less effective and harder to fasten. You should not attempt to just screw machine screws without first drilling a pilot hole.

If you have your heart set on using machine screws with your wood project-perhaps for aesthetic reasons-there are ways to go about it, such as fitting inserts into the wood and then screwing your machine screws into that.

But why are machine screws unsuitable for use with wood?

For one thing, while we would always recommend drilling a pilot hole before screwing into wood, wood screws are designed to work their way in without any assistance, much like a corkscrew.

They have a sharp, pointed tip and a wider thread for digging into the wood. In contrast, machine screws do not have to burrow into the material they are screwing into, and so do not have either a pointed tip or a wide thread.

This lack of a broad thread, in particular, is what makes them unsuitable for use in wood, as it will require considerably less force for a machine screw to be yanked free of its hold, especially given that wood is softer than metal.

The smaller thread of machine screws is not a problem when used in their intended setting as the thread they are screwing into is engineered to fit with the screw, and the material is considerably stronger than wood, so it would take much more force to strip the thread.

But Wait, There’s More…

Want to dig a little deeper and learn how you can make use of your machine screws in your next wood-based DIY project? Read on, and we’ll cover all the details.

Everything You Didn’t Know About Machine Screws

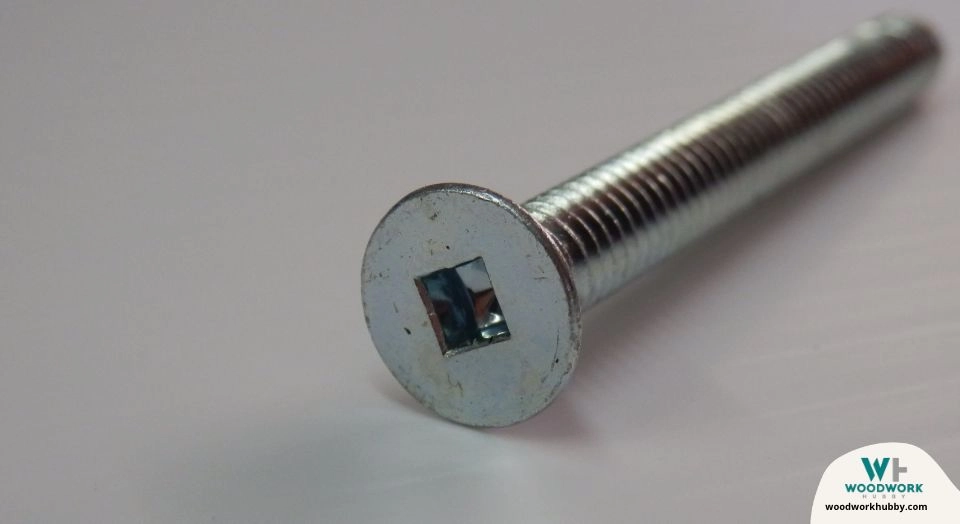

So, we’ve talked about the smaller thread that machine screws have compared to their wood screw alternatives, but what about the head? The head is the part that you turn with your screwdriver, and the designs are different between machine and wood screws.

The primary functional difference is that wood screws are usually designed to screw into the point where the top surface of the head is flush or slightly recessed with the face of the wood.

To this end, they have a tapered underside and a flat top. This prevents the screw from impeding anything that needs to mate up to the surface of the wood and makes it so you can fill in the screw hole and sand it down smoothly, hiding the screw if that is what you intend.

Machine screws, on the other hand, cannot dig into the material they are screwing into because that material is metal, or something similarly hard, and so they often do not have that tapered underside that allows wood screws to burrow in until they are flush.

Instead, machine screws tend to have something more aesthetically pleasing, such as a domed head, as they are more likely to be visible.

Of course, there are exceptions. Some wood screws are designed to fasten brackets-such as metal door hinges, in place and may have a flat underside to the head. Similarly, some machine screws are designed to fit into a countersunk recess so that they are flush with the surface of the material.

However, the majority of generic wood screws will be designed to sit flush, and the majority of generic machine screws will not.

Machine Screw Thread

Regarding the thread itself, it will hold to some degree if you can get it screwed into the wood. Remember, though; these screws are not designed to dig their way into the wood, so merely getting them in the first place will be a challenge.

And if you pre-drill the hole sufficiently to make getting the screws in easier, you will likely be weakening the already weak hold the screws will have. Learn more about machine screw threads.

However, if you get them in, they are not entirely ineffective. You could use small machine screws for very minor tasks, such as hanging light objects. Anything even remotely structural, or anything that requires a secure fixing, should use the correct screws only.

Why Thread Matters

Wood is a very pliable material. That is how wood screws can wind their way into the wood without a pre-drilled hole. It is this very same attribute that makes the machine screws unsuitable. Since their threads are considerably smaller than the thread of a wood screw, they had easily be pulled free.

The broader thread of the woodscrew provides more surface area to be in contact with the wood, meaning that more wood has to be broken through in order to pull the screw out.

Conversely, you cannot use a wood screw in place of a machine screw, as the thread will be too wide to fit, and there will likely be absolutely no give in the material that you are screwing into.

If you are screwing through something, such as thin metal, you may be able to get the wood screw to take hold if the hole is wide enough (but not too wide), but it will look unprofessional.

Additional Information

There are times when you might want to use machine screws in wood, despite everything you have just read. This may be because looks are essential on this particular build and you prefer the look of the machine screws.

It could also be because you want a specific kind of head-such as a hex or Torx screw, and can’t find wood screw variants of it. If this is the case, fear not, there is a way.

Threaded Inserts

The easiest way to make your wood compatible with your machine screws is through the use of threaded inserts. These are small metal tubes with a threaded inner face that is suitable for machine screws. Meanwhile, the outer face is designed to grip the material they are inserted into.

There are different designs, but two standard methods of fitting the inserts involve hammering them in so that pronged teeth dig into the wood, or screwing them in like you would with a regular wood screw.

Once that is done, you can screw your machine screw into the insert, and it will for as strong a hold as it would have done in a metal fixing.

Pre-Drilling

Wood can be a little tricky to deal with at times. It is very pliable, so it can be tempting to just go at it with your screws. At the same time, there are inherent structural weaknesses that can be unintentionally exploited by not pre-drilling the hole, such as weak points along the wood grain.

When you screw into the wood without drilling, the screw pushes the material aside, unlike a drill piece, which cuts the material away. If the wood is brittle, or if you are screwing into a particularly weak spot in the material, this can cause the wood to split.

Does pre-drilling mean a clearance hole? This article gives a full explanation of clearance holes.

On the other hand, if you pre-drill the wood and do not get the correct size, you risk reducing the hold of the screw to the point where it is no longer strong enough for the task.

The best practice is to drill a hole as wide as the thread in the wood that you are screwing through, and a pilot hole as wide as the shaft (not the thread) in the wood that you are screwing into. This reduces the amount of wood that is being pushed aside when you screw into it, and thus reduces the likelihood of cracking.

For a better explanation of why you should Pre-drill, be sure to take a look at this article which explains it fully.

The Right Tool for the Job

When screwing into wood, you will often need to apply more force than you would when screwing a machine screw into a threaded hole. This makes it more important to use the right screw bits.

If you are not particularly handy, you could be forgiven for thinking there are only two types of screw-slotted and crosshead, also known as Philips. While this is false in the sense that there are more types (posidrive, hex, Torx), it is also false in the sense that are different sizes and shapes of each.

Crosshead screws are notorious for “rounding” when the screwdriver skips, which often happens when applying a lot of force while using a screw bit that is not quite the right size.

It is best to have a selection of screwdrivers on hand when tackling jobs like this. Be sure to try a few different bits in your drill, and see which ones fit the best. Once a screw has rounded, it can be very difficult to wind all the way in or out. If this happens, I suggest throwing away the screw and using a new one.

Conclusion

Like I always say, If a job is worth doing, it’s worth doing right! So be sure to use the proper screws when screwing wood. Machine screws should only be used when using a threaded insert whilst giving you the flexibility of losing or tightening the machine screw often. I hope that this article was very useful to you so that you may enjoy your time in the workshop.

-

What Is Cedar Wood Used For? (Why I Stopped Using It On Some Projects)

Cedar is one of my favorite wood types because I am tasked with perpetually protecting some of my passion projects. It is one of the most resilient woods out there, and I often find myself wishing that all woods were like Cedar because I cannot really use it for all projects. Cedar wood is used

-

12 Beginner Wood Carving Projects Anyone Can Carve

Beginner Wood Carving As a woodworker, I believe woodcarving is one of the simplest forms of woodwork anyone could get involved in. If you start out with the most basic projects first, you can quickly develop the skills and the enjoyment to continue the hobby. I find I get a great sense of achievement from

-

9 Essential Tips For Screwing Into MDF

MDF seems to be the one thing that scares most people whenever they need to screw into its edge. I have been a cabinetmaker for the last 20 years and screwing MDF together is something we did every day.All of the apprentices would be always asking how to screw into the edges of MDF without

-

Maximizing Savings with Bulk Purchase of Wooden Cutting Boards for Your Restaurant

Running a successful restaurant business requires a delicate balance between offering top-notch culinary experiences and managing operational costs. One often overlooked but significant way to save money is by purchasing wooden cutting boards in bulk for your staff. These humble yet essential tools are the unsung heroes of any kitchen, and opting for cost-effective options

-

Top 5 Best Portable Table Saw For Fine Woodworking

Are you struggling to find the perfect portable table saw for your fine woodworking projects? I know exactly how daunting that can be, having faced the same hurdle once upon a time. After many years of working as a contractor, I have used many table saws and so I decided to identify the best portable

-

How To Remove Sticky Residue From Wood Table Top (It Works)

I totally get it. That unsightly sticky residue on your beautiful wooden table top just isn’t fun, is it? But how to remove sticky residue from wood table top without causing damage? After much research and plenty of experiments — some successful, others not so much — I’ve compiled quite a variety of methods to