Medium-density fiberboard or MDF is a type of engineered wood that involves defibrating softwood or hardwood into fibers and then adding a resin or wax binder to make panels. The density of MDF is greater than plywood, which has you curious about something. Can you use pocket holes on MDF?

Pocket holes can be used on MDF, especially with coarse screws such as Kreg screws. MDF is known to splinter or comes apart when drilled, but Kreg screws might be able to prevent that due to their shape.

In this article, I’ll talk further about pocket holing particleboard, including which screws to use, how it’s done, and what your other fastening options are. Make sure you keep reading, as you won’t want to miss it.

Are Kreg Screws Good for MDF?

You’re interested in proceeding with pocket holing MDF, and you know you need coarse screws. Can you use Kreg screws for the job?

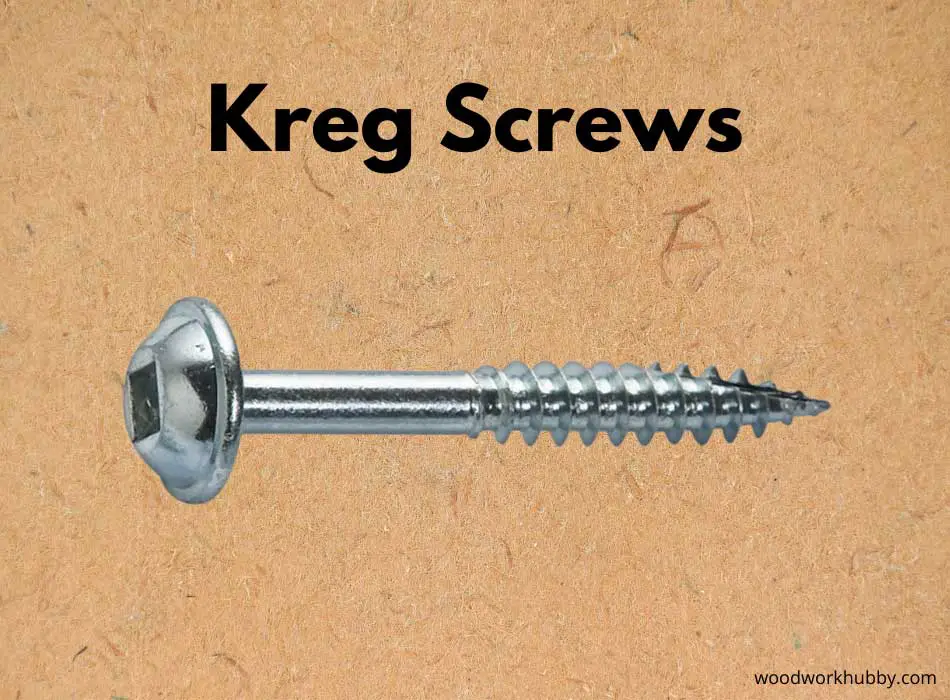

Kreg screws are especially recommended for pocket holing MDF since they’re coarse and designed to reduce splitting. Unlike other screws, Kreg screws are made just for pocket hole projects.

Be sure to see my article on How strong is MDF? Its limits may surprise you!

Here’s a little bit of background. Kreg is a tool brand that has been many woodworkers’ best friends for more than three decades. Kreg pocket hole screws are designed for longevity. They feature case-hardened steel that never breaks, snaps, or bends.

Sometimes pocket holes are ideal to help stop wood racking. Find out what that is here.

The shank of the screw is smooth to bring the joint together so pocket holing is never easier. The square drive at the top of the screw limits slippage while you drive the screw in. A self-tapping tip prevents splitting while the flat-bottomed head fits right into a pocket hole like it was always meant to be there.

These are the Kreg screws that I use and work extremely well.

Compared to regular woodworking screws, there is a difference between them and Kreg screws. The underside of woodworking screws tends to be conical rather than flat like Kreg screws. The purpose of the flat shape is to send the drilling force to the screw tip. This prevents pocket deformations that break the wood.

The makers of Kreg say that you won’t need a pilot hole, but I always ere on the side of caution and recommend drilling a pilot hole especially in MDF.

See my in-depth article on how to screw MDF without it splitting.

Can You Pocket Hole Particleboard?

Pocket hole joinery is a woodworking technique that entails drilling a 15-degree angle (or thereabouts) into a piece of wood. Then you’d use a self-tapping screw to connect the pre-drilled piece of wood with another.

Pocket holes are not recommended in particleboard as it does not hold screws well into the edge of the sheet. Particleboard is also prone to splitting or separating when screwed.

With this being said, you could try as long as you use a pilot hole and some wood glue.

Here is my guide on Can you use pocket holes in Melamine? Melamine usually has a particleboard center.

See my guide on what size pilot hole to drill here.

Also, I wrote about the wood glue I use and why it is the best wood glue to use on particleboard.

Woodworkers use pocket-hole joinery for all sorts of projects, including making window jambs, stairs, picture frames, leg rails, cabinet frames, face frames, and when doing edge joining or edge banding. If you’re building a wood project with curves or beveled corners, pocket holing is a must as well.

Pocket holing is advantageous for several reasons. You can attach two pieces of wood to one hole. That saves you time and reduces stress on the wood. You can also usually skip using glue, although some woodworkers will apply glue on the joints anyway to limit any gaps.

A lot of woodworkers hate pocket holes! I found this out recently. Check out my article which explains why do woodworkers hate pocket holes?

Particleboard, as we talked about in the intro, is quite dense, more so than plywood. An inch of domestic hardwood MDF can weigh 4.35 pounds (1.97 kgs), so it’s heavy too. Yet how drill-friendly is MDF? Can you pocket hole it?

Yes and no. Some woodworkers report that using a coarse-thread screw for the job is advantageous. These woodworkers usually will apply glue around the joint as well.

Other woodworkers have found that every time they try to drill into particleboard, the wood begins to separate, or it splinters and breaks. This is problematic considering that once the joint of a pocket hole is broken, you typically can’t fix it. That’s true when pocket holing any type of wood.

How Do You Pocket Hole MDF?

You’ve bought some Kreg screws and you’re ready to pocket hole some MDF planks. I recommend picking up a face clamp if you don’t already have one. A face clamp allows you to create joints that are flusher.

Kreg has its own classic face clamp that’s three inches or 76 millimeters. Their clamp is intended for wood that’s 2 ¾ inches or 70 millimeters thick. The grips are padded for better comfort and ergonomics.

Kreg KHC-Premium 3-inch Face Clamp

Check out this video below that shows you how to pocket hole MDF.

You should also have a cordless drill and a combination square. Once you gather all your supplies, here’s what to do.

Using a stepped drill bit, secure the stop collar on the shank and then tighten it. You want 1/8 inches of space from the pocket hole jig’s stop and the drill bit’s tip.

Put the clamp on the MDF, moving the stop until it’s right on the end of the particleboard. Then clamp your jig. Make one to two drilled pocket holes, with the latter recommended for building wooden cabinets.

You can also use several techniques for pocket-holing particleboard. Let’s go over them now.

Shelf-Nosing Technique

As the name implies, the shelf-nosing technique is for building plywood shelving. You’d drill pocket holes into the edge of the shelf. By clamping the shelf nosing onto a tabletop saw or another level surface, you can apply glue evenly on the plywood edge.

Then attach the MDF to the shelf nosing. By pocket holing, the plywood is angled downward. This may sound problematic, but it ensures a flush joint if you turn the shelf the other way.

Offset Technique

Another option you have is the offset technique, which is for building tables and other woodworking projects that stand on legs. A right-angle jig makes it easy for you to keep the table legs secure so you can put the apron on using pocket screws.

Cabinet Box Technique

I don’t recommend pocket holes for cabinet doors since the joints can show, but for a cabinet box, this method works. With your jig, make pocket holes across the cabinet box that are spaced eight inches apart. You can space the holes as far as 12 inches from one another depending on the length of your cabinet.

Apply some glue and add the Kreg screws or another type of coarse screw. Wood plugs in the pocket holes will make your cabinet box look nicer.

Face-Frame Technique

The last pocket holing technique is the face-frame technique. With a space blocker, align the face frames and then clamp their joints so the frames don’t move. Add pocket screws with a long square driver bit.

If you have scraps of MDF you can burn them or so you think! Be sure to check out my page showing the dangers of can you burn MDF?

How Do You Join Two Pieces of MDF?

You tried pocket-holing MDF, but each time you did, it splintered. You’re frustrated, as you need to join two pieces of particleboard, but you just don’t know how you’re going to do it. What are your options?

Two pieces of MDF can be joined strongly with spline or biscuit joints. Spline joints are pieces of wood that go between the grooves of two boards to make a loose tongue that’s then glued into place.

Here are the steps to follow.

Step 1

Align the two pieces of MDF that you want to attach as if they were already connected. Do you see any gaps or openings? Is there anything wrong with either piece of wood? If you answered yes to one or both questions, we’d suggest switching out one piece of plywood with another.

Step 2

On your table saw, replace the current blade with a dado blade. The size of the blade should be a quarter-inch, and it should be three-quarters of an inch over the tabletop. The saw’s fence needs to be on the blade’s right side and a quarter-inch away.

Step 3

Raise a piece of particleboard vertically, keeping it near the fence as you power on your table saw. Run the MDF under the blade. Then do it again with the second piece of particleboard. Both pieces should have a depth of three-quarters of an inch and a width of ¼ inches.

Step 4

Use fir plywood for the spline joint. With a miter saw, cut the wood until it’s ¼ inches (6.35 mm) by ¾ inches (19.05 mm) by 48 inches (1219.2 mm). Then put the wood into the dado channel. You might have to secure the channel with glue. The plywood should be on two sawhorses.

Step 5

Take one MDF piece and put it beside the plywood on the sawhorses. Then push the plywood strip’s longer edge on channel one into the second channel, tapping them using a rubber mallet.

Step 6

Place dual-bar clamps on the tops of the two pieces of wood. Then secure the bottoms with two more clamps until the pressure on the clamps is even. This will prevent warping. When you see glue coming out of the seams of the wood, the pressure on the clamps is enough.

Leave the clamps as they are for an hour until the glue dries.

Can I Use Countersunk Screws in MDF?

It is very hard to drill a pilot hole in a pocket hole on MDF as you would need a long drill bit. I’m lucky that I have one, but if you a new to pocket holes in MDF, I would steer clear and use the Kreg screws.

The Kreg screws work exceptionally well as they have a flat bottomed head on the screw.

Final Thoughts – Can You Use Pocket Holes On MDF?

Pocket holes can be used in MDF with success. You just need to take your time and use the right screws as I have shown above. I would also highly recommend the use of a pilot hole just to ensure that the MDF does not split. I hope this article has been of some help. Feel free to check out others I have written. Thank you and good luck!