If you’ve recently acquired a CNC routing device, you might notice two things; that its routing bits are detachable and it comes with a few bits. It is reasonable to think of when you might have to replace the bits since not every bit serves the same function, and you might need to replace a particular shaper sooner than you expect. So knowing about the bits’ longevity helps maintain expectations.

Router bits last up to 3 years with careful use and usually start becoming inefficient after 2 years. The material being routed, time spent routing, and the spin-velocity of the CNC device all affect the extent of a bit’s wear. Sometimes reshaping the bit instead of replacing it can suffice.

In this article, you will learn all you need to know about CNC bits, their longevity, and how to extend their lifespan. Paying attention to signs of a dulling bit can help extend their use, and this post will dive deeper into what you can watch out for so you can sharpen the bit before it wears out further.

How Do I Know If My CNC Bit Is Dull?

When you catch a CNC bit before it gets too dull, you can save your project from inaccurate routing, decrease the wear on the router and the routing bit, and you can sharpen the bit just in time. Below are some of the signs that your CNC bit is dull.

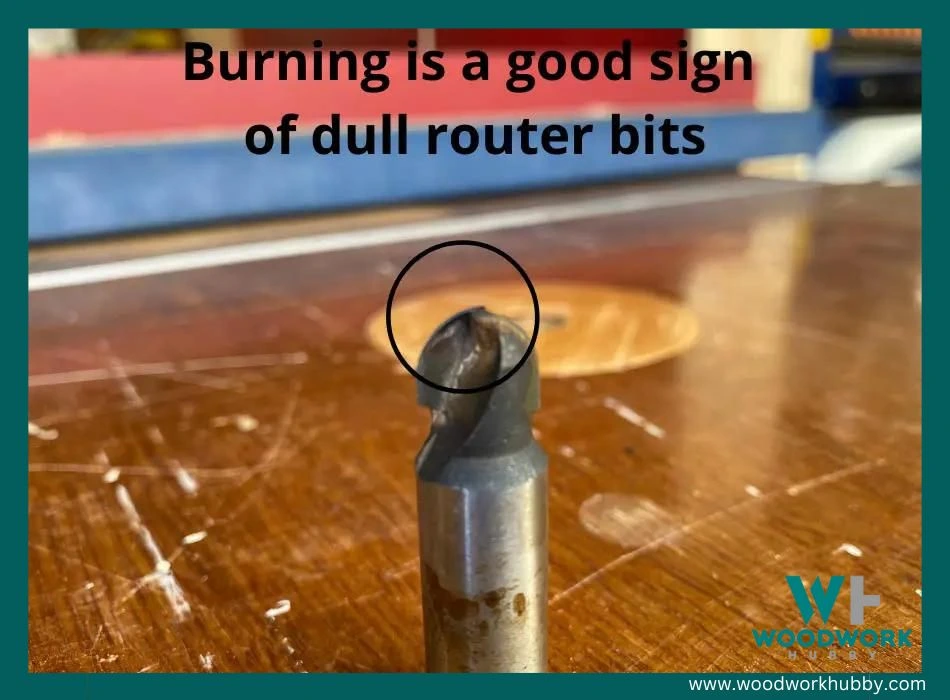

The surface gets burned more than it gets cut.

CNC routers use high-velocity spinning to cut through a material, provided a bit is sharp. Remember, the same router can be used for polishing and rounding, provided its bits are switched.

So ultimately, the high-velocity spin can serve different functions set apart by the front-bit. When this bit is sharp and flat, the surface gets sawed-open. However, most routers do not use such bits. They use deeper-reaching, sharper bits to cut through a surface.

If you notice the surface getting burned before it gets pierced, you can conclude that the bit is dull. A routing needle has to be dull enough for the high-velocity spin to cause burns via friction instead of cutting straight through.

That said, your CNC’s spin-velocity might be at the wrong setting to have the same impact. To be sure the burns occur due to the bit-dullness and not the spin velocity, you must look at other signs as well.

Be sure to read my full guide on how long do router bits last? You may be surprised!

The cutting bit feels smooth

This step requires a little tact and attentiveness. First of all, the bit must be removed from the device as it is risky to touch a routing bit while it is attached to a CNC. Secondly, the actual smoothness of the bit is harder to detect if you don’t pay attention.

Since the palm side of your fingers is tougher, it is easy to miss the sharpness of a CNC cutting bit.

However, if you run the back of your fingers over the cutting edge of the routing bit, you will feel a tiny sting if the bit is sharp. But if the bit has become dull, it will feel smoother.

If you have a brand new bit, the difference is easy to notice when you run a finger over one after the other. But if you’re in doubt, you can always check for other signs.

A black bit is turning white.

While not all CNC bits are polished or made dark, some come in all black or deep-brown color. These bits start getting white over time as they lose their sharper coat. One of the reasons behind such dullness is same-material routing.

While most CNC routers are used for woodworking, some machines are used for engraving metals.

If your CNC router bit is made with the same metal as the one it is trying to cut through. The high-velocity friction can lead to burning, smoothening, and piercing in that exact order. And while the raw material being worked on gets torn/pierced, the routing bit also gets compromised.

The first sign of this degradation is the loss of color in its upper coat.

CNC routers are good but are CNC routers accurate? Read my full article.

Shiny along a spot

This is a different manifestation of the black bit going white, albeit for bits that aren’t white. As mentioned earlier, routers can be used to polish a piece. If same-material routing is conducted frequently with a certain bit, it too gets “polished.” While that might not make a difference if the bit is used only for polishing.

But if the bit is supposed to be used for drilling and cutting, it will be inefficient. Even if you haven’t used a router bit to route/polish the same material, it can get polished/dull due to a host of other factors.

Ultimately, it doesn’t matter why a bit is shiny along the profile cutting edge, as long as you spot a shine, you can assume that the bit is dull. The rest can be deduced from the results.

Do Router Bits Wear Out?

When you get a batch of router bits, you might see marketing labels like “carbide reinforced” or “10x Long-lasting” on the package. Regardless of brand and durability treatment, router bits have a shelf-life, and you can expect to replace them down the line.

Router bits wear out with long-term use or short-term improper use. Resin can be a catalyst for this process as it provides a challenge for the cutting bits and makes them work harder, cutting years off the bits’ lifespan. To avoid wear-out acceleration, you should not use your router on plywood.

While plywood routing does take an immense toll on router bits, there are other factors that also accelerate the wear-out process. Here are some of the key contributors to Router bit degradation.

Time

The ultimate cause of degradation is the time spent using the router bit. The longer a bit goes on working, the more it gets worn out. Different bits degrade at different rates, but in the end, time turns every bit too dull to use.

The aim should not be to keep a router bit from ever getting dull. It should be to make sure the bit stays sharp for long enough to be worth its purchase price.

Bit Durability

A CNC router can accommodate Dremel Routing bits, but the latter is meant for a much slower-spinning motor. When you use a Dremel bit on a CNC router, you accelerate its wear-out process by attaching it to a much faster-spinning motor. This doesn’t apply to Dremel bits only.

Read my full article on Can you use Dremel Bits in a CNC router?

Whenever you take a bit meant for a slower-spinning motor and attach it to a higher-velocity machine, you expose it to more friction than it was intended to go up against.

Similarly, when you use a sturdier bit as the one tipped with carbide, you increase its ability to withstand friction and hence extend its lifespan. Taking a router bit meant for higher-speed motors/machines and adding it to a lower-velocity router can also have the same effect.

What matters is whether your router bit is more durable or less durable than the machine it is being used in.

Spin velocity

The machine that houses a router bit also affects the bit’s lifespan. If your CNC router has an extremely high speed, the bit will work more than when it is experiencing a lower routing speed. Spin velocity equals work.

Sometimes, higher spinning velocity does more harm to a router bit in a shorter time than low-spin does in the long run. But does that mean you should reduce the spin-velocity of your routing device? Absolutely not.

The project dictates the velocity at which your routing device should work which means. Some projects are destined to wear out your router bit.

Material density and resistance

In a project, the greatest factor affecting a router is material resistance. There are two ways to view resistance, which are the resistance period and the intensity of resistance. You want both of these to below in order to extend the bits’ lifespan.

For instance, plywood features tough adhesives that raise the intensity of resistance a router bit will face. A single sheet of plywood might not be thick enough to provide said resistance for a long period. A stack of hardwood might be deep enough to give less resistance but for a longer period.

Plywood is the worst material for router bits. Can your burn plywood?

Ultimately, both might have the same kind of impact on the router bit. The worst would be high-resistance exposure via intense resistance for an extended period: deep and long-lasting routine tasks on plywood will have the worst impact on the routing bits.

How Do I Know If My Router Bit Is Bad?

Routing bits often need to be sharpened or replaced. Some routing bits come in sets, and old ones are placed in a shoebox as new ones are used in their place. It is crucial not to run out of bits to use too quickly and to utilize a routing bit for as long as you can. But for that, you must know when a router bit is bad.

You know your router bit is bad when it seems to have difficulty in cutting or it’s burning the wood are among some of the obvious signs.

Among symptoms that can predict this point are: bluntness, smoothness, and the matte appearance getting shiny at points of contact. One can also judge whether a bit has been used too long by looking at when it was first acquired.

While the surest way to know if a bit is bad is to look at its performance, using an almost-bad piece isn’t ideal either. When you continue using a bit for too long without sharpening or replacing it, you incur other costs in the process. Here are the effects of using a bad bit in a router:

Ruined projects

This is the final sign of a ruined router bit and is one you want to avoid. Upon the longest use of a bad router bit, you will notice a badly carved project that will make you wonder if CNC routers are accurate in the first place. If you work with expensive materials like rare lumber, you do not want to reach this point, which is why you must look at other signs.

Higher power/time use

If your routing machine starts consuming more time or electricity to do the same job, you can safely assume that the routing bits have stopped being efficient. The only other possibility is that the material you’re etching has suddenly gone up in resistance. In other words, if you haven’t upgraded to a denser slab of wood, then the router is using more power and/or time because the router bits aren’t doing their job.

Impact on the CNC routing device

Finally, the most expensive adverse effect of a blunt bit is that it will increase the wear and tear of your CNC routing device. All CNC devices (like all machines) are expected to depreciate this time. This depreciation is the result of the wear and tear the machine incurs while working. The problem with blunt bits is that they make a machine work harder. As a consequence, the routing device experiences higher wear and tear than is standard for its make and model.

How Often Should You Sharpen a Router Bit?

The greatest contributor to a router’s wear and tear, aside from routing on tough material, is using a dull router bit. Therefore, sharpening the bit in time can extend your machine’s lifespan. For this, you need to look at signs that expose a dull bit, but you can also use usage time as a metric to make an educated guess regarding when to sharpen the bit.

You should sharpen a router bit after every intense use or whenever you see signs of dulling. Carbide-tipped router bits need to be sharpened 20 times less often than standard bits, but eventually, all bits show signs of being dull, which is when they should be sharpened.

Conclusion – How Long Do CNC Router Bits Last?

CNC router bits last as long as they can. For most semi-amateur use, that means 3 years, but some intense users have theirs wearing out completely in months. As long as you watch out for signs of dulling and sharpen the bit in time, your routing bits will go years without requiring replacement.

Above all, be cautious of using them on material like plywood, which contains tough adhesives that wear out a router bit.