I was watching a relative the other day trying to screw in some screws and no matter what he did, the screwdriver tip kept slipping out of the screws and ruining the heads. So why does the screwdriver or drill slip out of a screw?

A screwdriver or drill tip will slip from a Phillips head screw because the sides of the tip are angled and cause it to climb out of the screw and slip. The below items can also be major causes of your tip slipping.

- The Wrong Screwdriver or Drill Tip Is Being Used

- The Screwdriver Tip Is Worn Out

- The Screwdriver Is Not In Line With The Screw Direction

- The Screw Head Is Worn Out

- Not Enough Pressure Being Applied To Drive In The Screw

- Overtightening The Screw

Let’s face it, this happens to all of us at some point although if you learn why it happens, you can help prevent your drill from slipping out of a screw as often. I will explain each of these items in more detail below.

I will also mainly discuss Phillips or star headed screws in this article as slot head screwdrivers and screws are always very prone to slipping. There is no best practice for slot headed screws and hence why they are not being made anymore or are difficult to find.

What Is The Common Term For The Screwdriver Slipping?

When a screwdriver tip slips from a common Phillips head screw it is known as “Cam Out”. Some say Phillips head screwdrivers were designed to Cam out by this is not true according to the Patent Application.

The Wrong Screwdriver or Drill Tip Is Being Used

I find this is usually the biggest cause of your drill slipping from the screw head and you may not even know it. How is this possible you ask?

Screwdrivers and drill tips come in various sizes and types. You first need to make sure you are using the right type of tip. You may not have realized that you could be using a Pozidrive tip for a Phillips head screw.

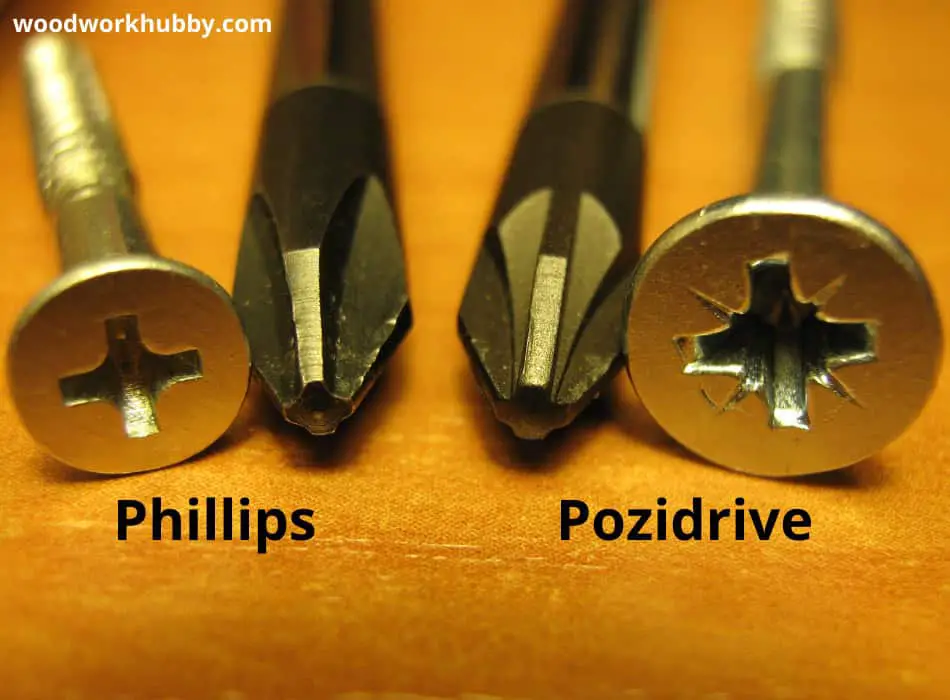

These are two very different head types and the images below will explain the difference.

Some people suggest that Pozidrive screws were invented to help eliminate the slipping that is common with Phillips head screws. The extra points of contact on the Pozidrive provide more surface area which enables the tip to grip on better.

While you could possibly get away with using a Phillips tip in a Pozidrive screw, you can’t use a Pozidrive tip in a Phillips head screw as the tip will not sit into the head deep enough and will slip at the first sign of resistance.

These are just 2 types of tips but I find these 2 are the usual cause of problems for anyone. The image below shows some of the other tips of screw heads you may commonly encounter in woodwork.

Size matters

Once you have selected the right type of tip for your screw it is important to select the right size tip. The tip should fit neatly inside the screw head without any wiggle room.

For example, Phillips head drivers typically come in P1, P2 & P3 sizes with P1 being the smallest and P2 is the most common. If you try to use a P2 tip in a screw with a P3 head, your tip will most likely slip and cause the screw head to get chewed up.

It is important to always check you are using the right size screwdriver tip for the screw you are trying to drive in.

The Screwdriver Tip Is Worn Out

Over time and with everyday use, our tools get worn and screwdrivers and drill tips are no different. It is important to regularly inspect your screwdriver tip for signs of wear.

This is what you should do if your drill stops spinning altogether!

A worn screwdriver tip will not seat correctly in a screw head and is prone to slipping.

I often see beginners trying to drive in screws with a worn tip and they have endless problems trying to get the screw in. The best thing to do is to throw the tip or screwdriver away and get another new one.

I can guarantee you will have an easier time driving in screws with a good tip.

The Screwdriver Is Not In Line With The Screw Direction

This is sometimes easier said than done as we often need to put screws in hard-to-reach places. When this happens, our screwdriver or drill cannot get fully in line with where the screw needs to go.

The screwdriver or the drill should always be straight with the screw and not at an angle. Trying to turn a screw with the screwdriver at an angle will always result in a stripped screw head.

If you find that the screw is going in at an angle and you can’t make the screwdriver line up with the screw, here are a few tips to get back on the right t

- Do Not try to drive a screw in like this as the result will be a stripped screw head which will mean you might not be able to get it out either

- Reverse the screw out and try making a new hole for it at an angle where your screwdriver can comfortably drive it in

- Use a shorter screwdriver for confined spaces

- If the screw is beside another object you could try using an extension on your screwdriver

- Try another area where you might be able to get at the screw more easily

The Screw Head Is Worn Out

It is important to inspect the screws you are using to ensure the head is not already worn out. If the screw shows signs of wear or is stripped out, your screwdriver will not be able to grip onto it to turn it.

I would strongly recommend you throw away any partially stripped or worn screws as these will more than likely cause you problems and ruin your project.

Screws are cheap enough to buy so discarding some bad screws will not hurt the hip pocket.

Not Enough Pressure Being Applied To Drive In The Screw

When you drive in a screw, you need to apply pressure to ensure the screwdriver tip stays inside the screw head. This applies to both manual screwdrivers and drill drivers.

If you let the downward pressure off, the screwdriver usually jumps up and slips on the screw head. This then causes the head to get stripped by the tip.

Of course, as your screw gets deeper into the timber it gets harder to turn. Once this starts to happen you need to apply quite a bit of downward pressure to keep the screwdriver tip seated in the screw.

In an ideal world, if you could keep an extreme amount of downward force then the chances of your screw tip slipping would be much less. This is easier said than done.

As we are humans and not machines, you can only apply as much force as you can at any given point. Just try to keep the pressure on the screw head until it is completely driven in.

What if your cordless drill stops spinning? This is what to do.

When Not To Use Force

Obviously, when you part so much downward force, there is always the chance the screwdriver tip could slip off and dent the timber or even worse, your finger! (I speak from experience)

This commonly happens when someone applies extreme amounts of force before the screw has even taken hold inside the timber. Screws are likely to be pushed off or fall off your tip as you start to drive in the screw.

I recommend when you just start to drive the screw, only apply a small amount of pressure until the screw bites fully into the wood. Once it has taken hold, you can then apply more force until the screw is fully in.

Overtightening The Screw

A screwdriver tip will commonly slip if a screw is over-tightened or it has reached its full depth. If your screw is flush to the surface, you should stop forcing the screw to go further.

Over tightening a screw can result in the tip of the screw head snapping off.

Other Helpful Tips

Apart from the items discussed above, there are a few other things you should consider before driving in a screw.

- Try drilling a pilot hole – A pilot hole makes the screw go where you want it to and also relieves a lot of friction on the screw turning.

If you try to drive in a screw into hardwood, there will be a huge amount of friction on the screw and will nearly always cause the screwdriver tip to slip and strip out the head. At worst, the head will snap off.

I always recommend drilling a pilot hole which I go into great detail why here.

- Use high-quality screwdrivers and driver tips – A screwdriver tips cops a beating from driving in hundreds of screws. I highly recommend spending a little more on good quality tools to avoid the pain of constant breakages.

- Avoid using slot head screws – These screws are the worts for slipping and are very difficult to drive in. Because of this reason, these screws are harder to find and are made less than the days gone by. I still however use these types of screws for very fine furniture work that require elegant detail.

- Consider using Pozi Drive – If you are fed up with your screwdriver slipping you could consider swapping over to Pozi drive screws. As explained earlier in the article, these types of screws seem less prone to slipping.

Conclusion – Why Does My Screwdriver Or Drill Tip Slip

Screwdrivers slipping from screws are common amongst all woodworkers and happens to nearly everyone. Whilst the tips I shared above will help this from happening as often, it will most likely happen to you again.

If you buy quality tools and be more aware of what is happening when you drive in a screw, the chances of your tip slipping again will be dramatically lower.