Workbenches are one of the most crucial aspects of woodworking yet vary from workshop to workshop. Alongside the size and the base type of the bench, what material is used for the workbench top also varies. I started with an embarrassing workbench 20 years earlier, and here’s what I have learned from 2 decades of trial and error.

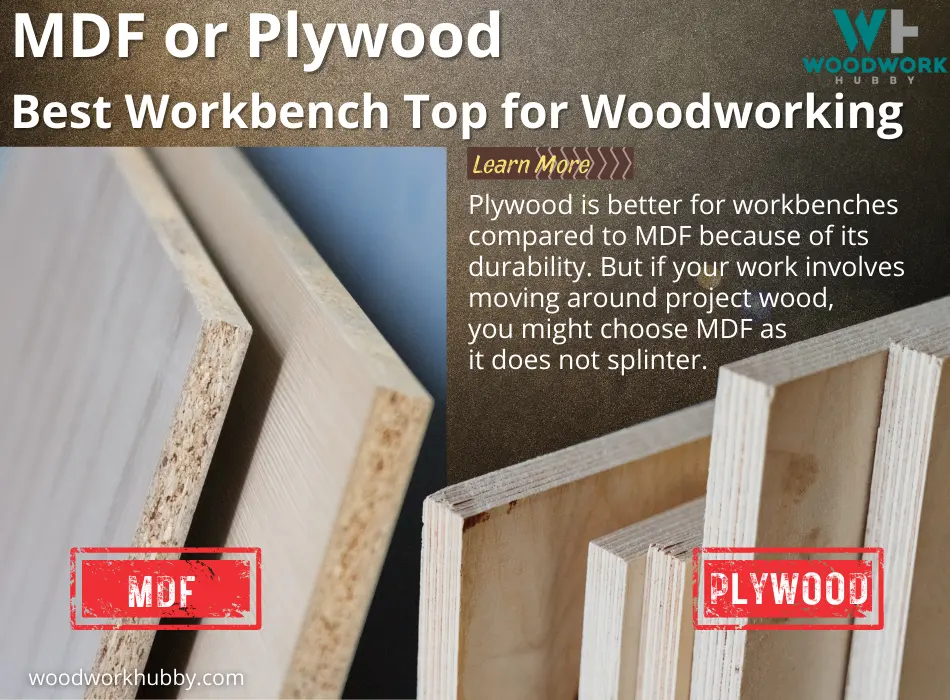

Plywood is the best workbench top if you compare it with other wood boards like MDF. It is more durable, doesn’t sag, can be fixed after an adhesive spill, and resists water better than MDF. However, it can be faulty, have knots, or may splinter. It is also more expensive than MDF.

In this article, you will learn everything you need to know about MDF and Plywood in the context of workbench tops. You will find out the respective pros and cons of these materials as well as how they compare with other top options. By the end, you will know everything you need to know to make an informed decision.

What Is the Best Wood for a Workbench Top?

The best wood for a workbench top is Hard Maple, as it is dense and plain. But most workbench tops are made from MDF or Plywood because they are more feasible. Among wood boards, plywood is the more durable option, while medium-density fibreboard or MDF is the flatter one.

As mentioned earlier, there are several options woodworkers have for their bench tops. I have used woodworking surfaces ranging from solid oak to cheap, thin plywood. And from 20+ years of experience, I have gathered that the following features are non-negotiable in lumber that is supposed to act as a workbench top.

Level and Balance

You can have a workbench that lacks durability and will give away in a month. But you cannot have a workbench top that doesn’t hold its own weight.

Balance and maintenance of a level to work on is literally the main function of a workbench top.

Fortunately, most options people consider are by default level and self-balancing. However, some are more than others. For instance, MDF is 100% flat, while plywood is not. But even plywood offers a “flat enough” surface.

Durability

The next thing you need from your workbench is durability. You can technically have a workbench that lacks durability. But it will be severely limited in the projects it will be able to handle. It might be okay for whittling and etching projects, but it will not handle larger project weights or heavy tools.

Your workbench should ideally be strong enough to handle projects that require power tools.

Longevity

Finally, the workbench top should resist the elements, at least in the workshop interior. Even the most durable material that rots in average climates or starts incurring water damage is counterproductive to the purpose of a workbench.

Longevity is important but comes third in priorities because most durable materials also tend to last longer in a workbench application.

Materials with high impact strength that are also prone to water damage are the exception here.

Neutrality

You want the workbench top not to interfere with your project. This means the surface must be hard and not leech any chemicals onto the project. You could be crafting wood boards or whittling bowls out of blocks. Both of these are food-contact surfaces. If the workbench top is arsenic treated, of course, it is not neutral and interferes with the project.

Advanced woodworkers want workbench tops that rank the highest across all the metrics covered above. That’s why they choose hickory or hard maple wood for their workbenches. For some of them, the choice is more for the aesthetic than durability, but it is true that hard maple and hickory benches beat wood boards in durability.

I still use solid wood for workbench tops for most of my projects. With over 20 years of woodworking experience, I’ve rarely found solid wood to miss the mark.

Beginners and intermediates should use an MDF workbench top because the material is cheap and easily available. It is hard to get a faulty MDF while finding the right quality fault-free plywood requires an educated eye.

Moreover, MDF is machine-pressed to be 100% flat. This can help beginners work on projects that rest on the bench under operation.

There are two types of projects. Ones that remain in the woodworker’s hands when they are being operated on and ones that need to be placed on the workbench while a tool is being used on them.

Whittling small wood rabbits is a project where the workbench material is irrelevant. The longer the project matter has to sit on the workbench, the more careful you need to be when selecting the workbench top.

With that in mind, here is the best workbench top material for your type of project:

- Thick Plywood – The project is in your hand 20% of the time or weighs less than 200 lbs.

- Thin Plywood – The project is in your hand 90% of the operating duration.

- MDF – The project is in your hand 10% of the time and/or weighs less than 100 lbs.

- Hard Maple – The project weighs over 250 lbs.

- Hickory – The project weighs more than 400 lbs.

Please note that the above assumes a standard saw horse base for all workbench tops. The sturdiness of the bench base is almost always factored in. The project can never weigh more than the total weight of the workbench.

MDF workbench works just fine for 70% of woodworkers. And for this conclusion, I draw from my experience where the MDF top is used in 7 out of every 10 projects. But when it comes to router tables and fixed power tools, as a table saw, I prefer using a sturdier top like plywood.

Is Plywood or MDF Better for a Workbench?

Plywood is better for workbenches compared to MDF because of its durability. But if your work involves moving around project wood, you might choose MDF as it does not splinter. Plywood is relatively expensive but will last longer and not sag under heavy wood.

A video about why MDF can a good choice for a workbench

To figure out which one is better for your specific work context, you need to consider the pros and cons of each. You’ll notice that some of the advantages don’t really matter to you. Similarly, some drawbacks will be of no importance to you. Disregard them and think about which one you prefer.

Pros of MDF Workbench:

It Is Smoother Than Plywood

MDF is machine-pressed to be 100% flat. It is made up of ground wood fibers that are pressured into a very specific mold. This minimizes the chances of dents and splinters. As a result, it is perfect for a workbench on which heavy objects are pushed vertically.

Faults Are Nearly Impossible

Because of the way MDF is manufactured, it is very easy to select. Even if you know next to nothing about wood boards, you can simply select an MDF board from a Home Depot shelf and have the exact same quality board as one selected by someone with decades of experience.

In contrast, plywood boards require a trained eye. A novice can end up selecting a board with faults and, even worse, knots. You can order MDF boards online, knowing you won’t get a board with splinters or dents. You don’t have the same luxury if you order plywood.

It Is Cheaper Than Plywood

Finally, you save money with an MDF workbench top if you don’t work with heavy material. The last part is very significant.

MDF is cheaper than plywood of equal thickness. But you don’t save money if your projects wear out the MDF top instantly.

MDF is a good money-saving choice for workbenches meant for beginner and intermediate projects.

Cons of MDF Workbench Top

It Can Start Sagging

An MDF workbench can save money only on small-scale projects. If the project wood is heavy, it can put pressure on the workbench top and make it sag. In contrast, plywood fibers’ perpendicular placement keeps the board from sagging. In this context, MDF’s flexibility works against it.

It Is Not Water-resistant

MDF is by no means water-resistant and can start soaking it up eventually. This means that even in an interior environment, the humidity will eventually get to it. Plywood, while not waterproof, is water-resistant.

Adhesive Spills Stick To MDF

Finally, a drawback that is rarely discussed is how MDF deals with wood glue and resin spills. Paper is made from wood pulp. MDF is made from wood fibers that solidified into a wood board with pressure and adhesives.

Removing adhesive from MDF is almost as hard as removing it from paper. The MDF wood fibers that stick to the glue on one end are stuck to the rest of the MDF on the other end. Removing the glue can create a dent in the MDF workbench top.

Who Should Use an MDF Workbench Top?

With the above pros and cons in mind, you can see why you should use an MDF workbench only:

- If you work on small-scale to medium-scale projects

- If you don’t use resin, wood glue, and liquid adhesives

- If your projects require sliding throughout the operation

- You’re just starting out.

Pros of a Plywood Workbench Top

Doesn’t Sag

Plywood is far more rigid than MDF. Where MDF lacks the rigidity required to carry heavier projects, it makes up in surface smoothness. The plywood pro of not sagging is the most valid for projects where heavy material doesn’t need to slide across the surface. Otherwise, the heavier the project, the higher the odds it will splinter the workbench top.

Removing Glue From It Is Easier

This is a very specific advantage that works only when you compare plywood to MDF. Hickory, Hard Maple, and plywood workbenches can all be fixed after an adhesive spill.

Is Relatively Water-Resistant

Plywood might not be 100% waterproof but is water-resistant for all practical purposes. Humidity and minor water spills don’t affect it. If you use a spray bottle during any part of your process, a plywood workbench top is better for your workbench.

Can Carry More Weight

Plywood of equal thickness to MDF is stronger than said MDF. If your workbench top is crafted from a single material, it better be plywood for heavy projects. But if your bench top is a hybrid, it can have an MDF surface with a sturdier base underneath.

Cons of Plywood Workbench

More Expensive Than MDF

The biggest drawback for a starting woodworker is that plywood costs more than MDF of equal thickness. That’s why I recommend using MDF for beginners.

Can Splinter

Plywood can splinter if certain bits dislodge from the adhesive interior. This is because plywood is rigid, and the bits that break off maintain their hardness.

Is Harder to Select

Plywood is a high-quality option for your workbench top only if you choose high-quality plywood. If you don’t know how to select high-quality plywood, you can end up purchasing plywood that isn’t as flat as you need.

Can I Use MDF for a Workbench Top?

You can use MDF for a workbench top in most cases because of its flatness and lack of wood grain. However, if your project is especially heavy, you need to use a sturdier material beneath the MDF or in its place.

Is Plywood Good for a Workbench Top?

Plywood is good for a workbench top but is quite expensive compared to MDF and other wood boards. You can get use it for almost any project as long as you’re careful to avoid splintered or faulty plywood. If your workbench requires sturdier top material, choose hard maple.

Final Thoughts – MDF Or Plywood: Best Workbench Top for Woodworking

Both MDF and Plywood work for a workbench top. But the rule of thumb remains that if you can afford to use high-quality plywood, avoid using MDF. MDF will eventually sag. Its benefits (lack of grain, flatness, etc.) can be leveraged by adding an MDF surface to a plywood workbench top. Again, that would be expensive, and I would advise starting woodworkers to avoid that.