Racking in woodwork will be familiar to anyone who has done more than a little woodworking in their lives. It is easily avoidable, but equally as easy to cause through the way you work with your wood, and can be the reason for no end of problems as you attempt to shape and work your piece of wood.

We’re going to explain how you avoid racking in woodwork, but first, let’s explain what it is. What is Racking in woodwork?

Racking in woodwork is when a timber object is pushed out of square or alignment and leans to one side. This can happen in bookcases due to incorrect clamping pressure or to the jaws on a woodworking vice due to pressure on one side of the vice and not the other.

Does this sound familiar? If you are a DIY enthusiast or a novice in the world of woodworking, there is a good chance it will. Many aspiring woodworkers have given up on projects believing they simply lack the ability necessary to work with wood.

There’s no need to panic; however, this is a simple problem that can be fixed by knowing what the cause is and how to avoid it. Read on, and I will delve a little deeper!

What Causes Racking In Woodwork?

Uneven Clamping In Woodwork Vice

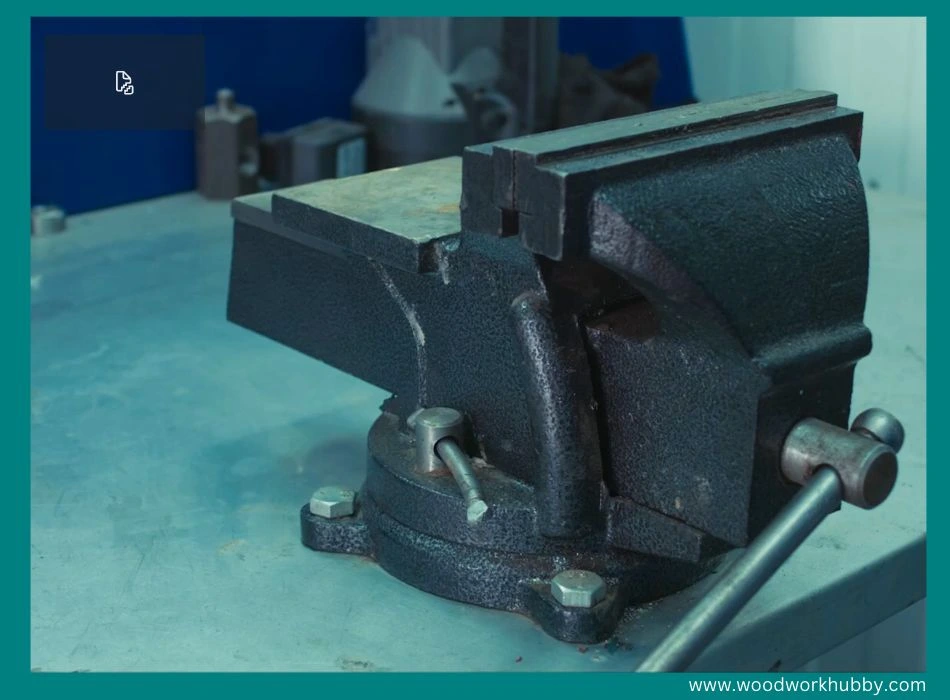

As mentioned above, racking happens when an object is pushed out of square or alignment such as the jaws on a vice when a piece of timber is clamped in one side only of the jaws. As the vice is tightened the jaws will rack.

You can’t sand, saw, plane, or perform any action on a piece of wood that moves every time you touch it. There are many different ways of securing a piece of wood depending on the size of the wood and the action you are performing, but the basic principle of wood racking is the same regardless. How to buy wood.

To describe what is happening, we will use a regular bench vise as an example. The vise features two rectangular timber pads that press against the wood when it is clamped; this is often more than enough to hold the wood in place securely. See which wood is best for a woodworking bench.

However, if the wood is placed on one side of the vise, the clamp is uneven. This happens because the side that has no wood in it, closes further than the side where the wood is, which causes the clamping pads to tilt away from being parallel with the surface of the wood. In effect, the wood is clamped at two small points, rather than evenly across the full width of the wood.

This tilting in the vise pads may be small and imperceptible, especially with larger, more robust vises, but the effect is the same. It happens the same way with other methods of securing wood.

Basically, any time wood is clamped between two surfaces; if it is unevenly clamped, racking can occur.

Incorrect Clamping

One common woodworking project is a trusty bookcase or similar square cabinet. During the construction of these items, we are sometimes required to clamp up the item until the glue dries.

Once out of the clamps, the item may have been clamped up incorrectly causing the cabinet to be out of square also known as Racking.

Sometimes a diagonal brace may be required to keep the item square and aligned.

Excessive Forces

These forces can come from many factors but the most common can be someone leaning or pushing against a table for example. If the joints are not strong, the legs can rack to one side causing the table to lean over.

Over time and repeated racking, the table joints can work completely loose and break apart.

What Types Of Woodworking Can Racking Affect?

In woodworking, most racking can occur in general furniture and cabinet-type items. These items include:

- Cabinets

- Bookshelves

- Storage units

- Woodwork benches

- Vices

- Chairs

- Tables

- Doorways

- Window openings

How Do I Stop My Workbench From Racking?

Diagonal braces should be added to workbench legs to stop them from racking. These braces need to run from the bottom of one leg to the underside of the worktop. A brace should be added to both sides and ideally running in opposite directions.

These diagonal braces will prevent the bench from racking while you are applying pressure to the bench such as during planning.

Why Does My Workbench Rack?

Over time the joints on workbenches can become loose which enables movements of these joints to occur. If left untreated, the joints will become increasingly worse to the point that your bench may wobble from side to side. This is commonly referred to as racking.

What Happens As A Result Of Racking?

The undesirable result of this is that the timber held in a vice can move far more easily while you are trying to work it, often tilting away from you or vibrating, which makes it considerably more challenging to get a neat result.

Also, a cabinet or opening that has racked and out of square will cause further problems such as a door or window will not fit properly. This is also commonly referred to as Racking in Construction.

In all cases, excessive racking will eventually lead to permanent damage and breaking of your woodworking projects.

How to Prevent Wood Racking

Learn To Use A Vice

The simplest way to prevent racking when working with wood is to clamp your piece in the center of whatever you are using to hold it in place. This ensures that the pressure is applied evenly since neither side will have more or less resistance than the other.

If you can’t clamp your piece in the center of whatever you are using to hold it in place, try getting a piece of wood of the same thickness and clamping it at the opposite side to the piece you are working on.

This should prevent the clamp from being uneven, but it is crucial that the second piece of wood be the same thickness, as a smaller or larger piece will result in the same problem.

If there are small differences in the thickness of the wood, you should be fine. It is worth remembering that wood is a very pliable material, however.

If you tighten the clamp around the piece of wood you are working on too much in an effort to close that gap, you risk marking the wood and ruining the finish on what you are working on.

Be sure to check the operation of a second-hand vise before clamping your best workpiece.

Check For Square

When building any sort of cabinet or opening, double check all sides are parallel and square when you apply clamps or fix these items into place.

For bookshelves adding a square backing board or diagonal brace can stop your piece of furniture from racking. Always double check during the clamping stage to ensure racking has not occurred.

On table legs, diagonal braces could be added as a decorative feature which will also prevent racking.

Types Of Vises That Can Contribute To Racking

There are many different kinds of vise that can be used in woodworking. And, while the basic premise of how they work is the same, they each have their own advantages.

Workbench Vises

Possibly the most commonly used kind of vise, these vices mount to the edge of your bench where they stay permanently. They are popular because they are usually at a good height for working while standing up without causing too much strain on your back or neck.

Face Vises

Typically, face vises are used for holding larger wood pieces in place so that they can be cut or drilled. These kinds of vices are similar to a workbench vise in that they can keep things in place vertically at the edge of the bench.

Where they differ from workbench vises is in the fact that they use the bench itself as one of the faces. The clamping edge is wound in, pressing the piece that you are working on against the edge of the bench.

This has the advantage of accommodating much larger pieces but at the expense of being larger and less portable. That is, it is relatively simple to remove a workbench vise and put it somewhere else, but a face vise will be more challenging to remove, and in some designs will actually be part of the workbench itself.

Quick Release Vises

This one isn’t so much a style of vise as it is a feature. Some vises-mostly workbench vises-have a quick-release lever that disengages the winding mechanism, allowing you to slide the vise in and out without having to wind it.

This kind of vise is especially useful for people who are alternately working on large and small pieces, and frequently need to open the vise up wide or close it down narrow to clamp the piece they are working on.

This feature is relevant here because the more pressure you clamp something with, the harder it is to use the quick-release feature.

And, given that the uneven pressure described above often means you have to clamp the vise more tightly to get an effective hold, failure to achieve an even clamp will likely result in you having to clamp the vise too tightly to use the quick-release functionality.

Will Wood Racking Ruin My Work?

Wood racking will make your work rougher and less accurate. If the wood is moving, sliding, and vibrating while you are trying to work it, it will not be possible for you to get as clean a finish as you would with a securely clamped piece.

That being said, whether it would ruin your work will depend on what it is you are working on. If you are making a small, delicate item with intricate features, wood racking would absolutely make it considerably more difficult-if not impossible-to finish your piece to the standard you desire.

However, if you are making some storage shelves for your garage and the look isn’t necessarily critical, you can probably get by.

This would also be the most common situation when someone would have to live with wood racking, since it most commonly occurs when trying to hold wood without a vise, such as would be the case with a DIYer who does not have a vise to use in the first place.

Avoiding Wood Racking Without a Vise If you are working without a vise, the best way to avoid wood racking is to have a friend help you out.

If you can secure one end-perhaps with your knee-while they secure the other, you should be able to hold the piece firmly enough that wood racking does not occur, allowing you to get as smooth a finish, or as clean a cut, as possible.