While I love working with wood, I rarely use it for cabinets. I’ve found that plywood is great for cabinetry and medium-scale projects. A type of plywood can work well for sheathing as well. But did you know that there are types of plywood that work outdoors as well? You can use them for fences, door frames, and even birdhouses.

The best plywood for outdoor use is BWP-grade plywood that is reinforced with pressure treatment. Marine-grade plywood of any sort will hold up for up to 5 years in most outdoor use cases, while pressure-treated plywood can last 2 to 3 years without any additional waterproofing.

In this article, you will learn more about each type of plywood that can be used outdoors. You will also find out which context calls for which plywood and why. By the end of this post, you’ll know all you need to know about using plywood outdoors, including my tips to make it last longer.

Bookmark this post to have 20 years of woodworking experience at your fingertips.

| Plywood for Outdoor Use | Use context |

|---|---|

| ABX Plywood (Marine Grade Plywood) | Water-adjacent use. Aesthetic outdoor projects. |

| ACX Plywood (Marine Grade Plywood Sheets) | Exterior walls in a humid climate. |

| ADX Plywood (Marine Grade Plywood with faults) | For non-aesthetic functional use |

| BWP Grade Plywood (Boiling Waterproof Plywood) | Humid and steamy environment. Rainy Outdoors |

| MR Grade Plywood (Moisture Resistant) | Outdoors with an average humidity |

| BWR Grade Plywood (Boiling Moisture Resistant) | Humid Outdoors with low rainfall risk |

Issues When Using Plywood Outdoors

When any type of wood or wood board is used in an exterior context, it has to face relatively harsher conditions. The most significant factors that can age, warp, or deteriorate these materials are sunlight, moisture, and potential infestation (rot/insects). Different construction materials have different resilience when it comes to these.

Plywood in exterior settings doesn’t have a rotting or insect infestation problem. However, it can warp due to heat and can eventually degrade from exposure to moisture. So the plywood that is manufactured for exterior use has to be constructed to offset both of those factors.

It must be able to maintain its shape and structure even in extreme heat, and it should be borderline waterproof, if not completely water-resistant.

A video showing the five reasons to use marine-grade plywood.

What Type Of Plywood Is Best For Outdoor Use?

Marine-grade plywood is best for outdoor use since it can resist water damage, which can occur with constant exposure to moisture. The more humid the outdoors, the more important it is to use marine-grade plywood.

Marine-grade wood or wood boards are used in ships and boats but are not meant to be submerged in water. A boat’s deck might be made from marine-grade plywood. You will have unrealistic expectations if you mistakenly assume that marine-grade plywood is just as waterproof as a ship’s hull.

Marine-grade plywood is waterproof to an extent. It doesn’t get damaged by humidity and water spills. But if it is drenched in water, it can start incurring water damage. It might also expand if it is placed under a water leak.

See what happens when plywood gets wet. I wrote about this after I got caught coming home in a storm.

Since any plywood that can pass the moisture resistance test can be labeled marine plywood, it is pretty important for woodworkers to know the different levels of water resistance and their corresponding grading/category.

Having this knowledge can help you choose the best plywood for outdoor use if you’re in an exceptionally humid region.

Which Plywood Is Waterproof?

BWP-grade plywood is a type of marine plywood that is waterproof enough to withstand boiling water. This is the highest threshold for water resistance documented, making BWP-grade plywood the most resilient plywood in water-adjacent settings.

Best Exterior Plywood

BWP plywood can be exceptionally expensive. Moreover, it can come in thickness and dimensions that do not match your project specifications. So what can you do to get plywood that works for the exact use case if you can’t find marine grade sheets to match?

You can use a sealant, waterproof primer, or paint to make sturdy plywood water-resistant enough for exterior use. This can work quite well in areas that aren’t too humid or hot.

In a climate where moisture is abundant, or the heat and cold can vary quite drastically, even BWP plywood can start to wear out. Ultimately, all plywood has a shelf-life, especially in the outdoors.

An experimental video of testing BWP Plywood’s resistance to heat and other harsh conditions.

How Long Does Plywood Last Outside?

Untreated plywood can last outdoors for up to two years. After that, it can become structurally unsound and practically useless. On the other hand, high-quality waterproof plywood can last outdoors anywhere between 35 and 50 years, depending on the load it bears.

The longevity of the plywood depends on the following factors:

- Its water-resisting ability – The higher the grade of the waterproof plywood is, the longer it will last.

- Its heat exposure – The less hot the summers and the daytime get, the longer the plywood can last.

- The humidity in its surroundings – The more humidity in the environment, the higher the toll it takes

- The load it bears – The heavier the load of the plywood, the quicker it will buckle.

All in all, you can make plywood last longer by opting for higher-grade waterproofing, using shade to reduce sunlight exposure, and reducing the overall load on the plywood.

But weight and sunlight aren’t the only causes of plywood’s early demise. Insects and microbes can infest plywood and make it collapse even under the lightest weight.

What Plywood Is Rot Resistant?

Pressure-treated plywood is rot-resistant because microbes and insects cannot infest it. The organic material in the plywood is so completely engulfed in a rot-resistant chemical that the plywood itself becomes rot-proof.

Pressure-treated plywood can be used in exterior settings to minimize water damage alongside the chances of termite infestation and molding. It, however, cannot be left out in the rain perpetually as water does affect it.

Just because some types of plywood can survive rain, it doesn’t make them waterproof.

Exterior plywood, like pressure-treated plywood, can sometimes be seen as waterproof because it rains outside. Just because some types of plywood can survive rain doesn’t make them waterproof, though.

Is Exterior Plywood The Same As Waterproof Plywood?

Exterior plywood can be waterproof but is not always waterproof. Waterproof plywood is more resilient against water damage and humidity exposure, while exterior plywood can resist water damage to an extent but is far from being 100% waterproof.

The table below covers how these two can differ.

| Pro/Cons | Exterior Plywood | Waterproof Plywood |

|---|---|---|

| Pro | Is insect-resistant | Is water-related rot resistant |

| Con | Can incur water damage | It is more expensive than the alternative |

| Pro | Can withstand sunlight exposure | Doesn’t get damaged too easily |

| Con | Might not be able to bear extra weight | It can be vulnerable if cut |

| Pro | Is easy to acquire | Can survive heavy rainfall |

| Con | It can be damaged by heavy rainfall | It is available in limited dimensions and thicknesses |

The above comparison shows that both types of plywood can be contextually the best in different scenarios. But no matter the context, marine-grade plywood always beats non-marine plywood in its ability to resist water damage.

Which Is The Best Waterproof Plywood?

The best waterproof plywood is BWP grade plywood, which is the highest grade marine plywood commercially available. However, exterior-grade plywood, like the pressure-treated variety, is significantly water-resistant and can be used in exterior settings.

Before selecting the right plywood for your region, you must ask yourself a few questions regarding its use case and your personal context. I have listed these questions below.

How Often Does It Rain In My Area?

If it rains all the time, then you cannot rely on merely water-resistant plywood. You need 100% waterproof plywood for exterior use. But if you live in Nevada, then waterproofing isn’t as big of an issue as heat exposure.

In that case, pressure-treated plywood that can resist warping is a much better fit for dry Nevada outdoors.

See my article on what happens if plywood gets wet.

How Much Sunlight Will The Project Receive?

This question isn’t the same as “How sunny is my region?” If your outdoor plywood project is covered with a significant shade that prevents direct sunlight exposure, it doesn’t matter how sunny your state is.

If the plywood itself will sit in full sun, then the duration of sunlight, as well as its intensity, will dictate which option is better. In most cases, exterior-grade plywood will fare better than marine-grade plywood.

What Is My Budget?

Finally, you need to consider the budget, as it can become the deciding factor in the type of plywood you choose. If you’re on a shoestring budget, then you might need to take regular plywood and coat it in a layer of waterproof primer.

If you have more money than the project is worth, you might as well use a BWP grade plywood in a region where it never even rains.

The only time you should disregard budget constraints when making your choice is when marine grade plywood and pressure-treated plywood are within your reach. In that case, you can make your decision more about the specifics.

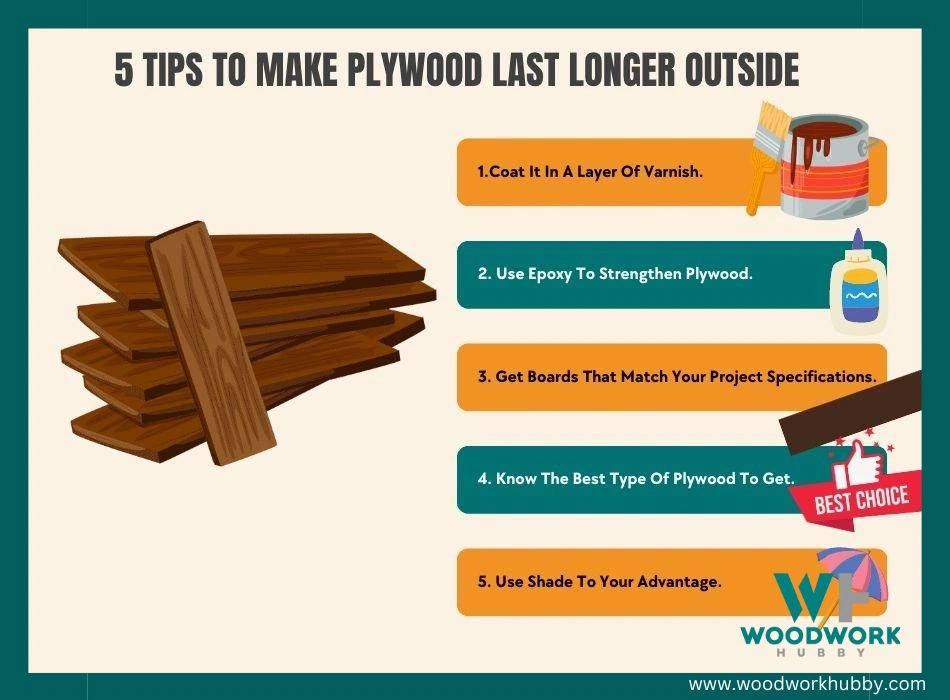

My 5 Hot Tips To Make Plywood Last Longer Outside

If you read this blog, you probably already know that I have over two decades of woodworking experience. Plywood is one of the wood boards I have often used in my work in both interior and exterior settings. Here are my top 5 tips to make plywood last longer.

Coat It In A Layer Of Varnish

Most woodworkers often ignore the positive potential of varnish for plywood because the plywood they use is supposedly waterproof. As mentioned earlier, anything but BWP grade plywood can still incur water damage.

The more protected your plywood is, the longer it will last. Many plywood boards positioned as waterproof have a thin layer of clear waterproof material over them.

If it wears out or is sanded off during construction, the plywood becomes vulnerable. That’s why it helps to coat the project in varnish once it is done.

Moreover, many types of varnish can reflect UV radiation which means the underlying material (plywood) doesn’t incur as much heat damage.

Use Epoxy To Strengthen Plywood.

If you truly want to turn a standard plywood board into an outdoor-use plywood sheet, you simply need to use an epoxy sealer. An epoxy sealer can minimize the effect of impact, sunlight, and water on any material, including plywood.

Of course, you don’t have to use epoxy resin to coat plywood you have varnished or vice versa. Only one type of material must be used in this context.

Get Boards That Match Your Project Specifications

One of the best ways to minimize damage to plywood and maintain its longevity is to avoid cutting it. In projects like fences and shed-building, you can afford to keep plywood boards almost unaltered.

But in projects like birdhouses and smaller crafts, the boards need to be cut up. The closer the plywood boards are to the plans of your project, the longer the overall project will last.

Outdoor Grade Plywood – Which Should You Use

This is 99% of the secret. If you get the plywood that fits the use context, you won’t have to worry about it for three to four decades. That’s why most of this article centers around the different types of plywood that can be used in exterior settings.

I went over the use cases earlier, but here is a little more about the plywood types:

- ABX Plywood – Marine Grade Plywood – It is fairly expensive and is good-looking. You can use it for projects that are meant to have aesthetic value.

- ACX Plywood – Marine Grade Plywood Sheets – Can be used for veneering in similar contexts as ABX plywood.

- ADX Plywood – Marine Grade Plywood with faults – This usually makes up the less exposed parts of the project that use ABX plywood. It is more knotty.

- BWP Grade Plywood – Boiling Waterproof Plywood – This is the most waterproof plywood and can be considered 100% waterproof for all practical purposes. You can use it in steamy, humid, and rainy environments.

- MR Grade Plywood – Moisture Resistant Plywood – Since this plywood is moisture resistant only, you cannot use it where it will be exposed to rainfall

- BWR Grade Plywood – Boiling Moisture Resistant – If the project will be exposed to rainfall, but it will be no more than a drizzle, then BWR Grade plywood with a coat of varnish should suffice.

Use Shade To Your Advantage

Since plywood sheets are held together with an adhesive, heat is not good for them. The more malleable the adhesive layer becomes, the less rigid the plywood can be. I use shade to make plywood last longer.

It isn’t just the UV-resistant varnish’s job to keep your plywood protected from sunlight. The more defenses you erect, the longer your plywood will last. The best thing about this tip is that it works for all types of plywood.

Now if you are looking for the Best Plywood For Cabinets, please refer to the link provided.

What Is The Difference Between Exterior Grade Plywood and Pressure Treated Plywood?

From my experience, exterior-grade plywood and pressure-treated plywood differ in composition and use:

- Composition:

- Exterior grade plywood: Layers of bonded wood veneer.

- Pressure-treated plywood: Treated with preservatives for moisture and decay resistance.

- Environmental Resistance:

- Exterior grade plywood: Resists elements but not moisture as effectively.

- Pressure-treated plywood: Highly resistant to moisture, decay, and insects.

- Use Cases:

- Exterior grade plywood: Suited for outdoor use but not in direct contact with soil or water.

- Pressure-treated plywood: Ideal for applications involving soil or water contact, like decks and garden beds.

- Appearance:

- Exterior grade plywood: Usually smoother and more finished.

- Pressure-treated plywood: May have a greenish or brownish tint due to treatment.

In essence, exterior-grade plywood is for outdoor use with less moisture resistance, while pressure-treated plywood is designed for superior durability and protection against moisture and decay.

How Long Will Exterior Graded Plywood Last Outside?

Generally, well-constructed and properly maintained exterior grade plywood can last anywhere from 20 to 40 years when exposed to the elements.

Regular maintenance, including sealing or painting the plywood, can significantly extend its durability by providing a protective barrier against moisture, UV rays, and other environmental factors.

I have found that with proper installation and ensuring that the plywood is kept away from prolonged direct contact with water or soil can also contribute to its longevity.

Most Resistant Plywood

Marine plywood is considered the most resistant type of plywood available. It is specifically designed for high moisture and wet environments and is highly resistant to water, decay, and insects.

Marine plywood is made with high-quality wood veneers and adhesive, and it undergoes special manufacturing processes to enhance its durability and water resistance.

While marine plywood is exceptionally resistant, it’s essential to note that it can be more expensive than other plywood types due to its specialized construction and superior resistance properties.

Final Thoughts – Best Plywood For Outdoor Use

The best plywood for outdoor use is determined by the use case. Marine grade plywood is the most aesthetic option, while a varnish coated B grade plywood is the cheapest one.

Depending on the plywood type you choose, your project will last anywhere between 5 to 30 years. That’s a wide range, which reflects the variety of options you have among outdoor plywood grades.

FAQ’s

Is CDX Plywood Exterior Grade?

CDX plywood is generally considered exterior grade. The “CDX” designation refers to the type of plywood and its suitability for various applications:

- “C” stands for the face quality, which is typically rated as “C” grade. This means that the face of CDX plywood may have some knots and imperfections but is still suitable for exterior use.

- “D” represents the grade of the back of the plywood, which is often of lower quality than the face but is still acceptable for exterior applications.

- “X” indicates that the plywood is rated for exterior use, meaning it is designed to withstand exposure to the elements, such as rain and moisture.

Is Marine Grade Plywood Better than Pressure Treated Plywood?

Marine grade plywood is superior to pressure-treated plywood for applications requiring exceptional moisture resistance and durability, especially in marine and water-exposed environments.

How Do You Keep Plywood From Rotting Outside?

To prevent the plywood from rotting outside, apply a waterproof sealant or paint to all surfaces, edges, and cut ends of the plywood to create a barrier against moisture. Elevate it above the ground to avoid direct contact with soil, and ensure proper drainage to prevent water accumulation.